Orskov Foods – Processing blackcurrants (and more!) in Denmark

When the IBA Executive met in Denmark last April, we were invited to visit one of the privileged partners of our Danish grower members: Orskov Foods. A most interesting and pleasant visit.

Welcome at Orskov Foods!

Highly modern equipment, cleanliness, tidiness – and the warmest welcome at Orskov Foods. While we are choosing among a whole range of sandwiches (bigger than any burger in the world!) and drinks (from smoothies over juices to cold coffees), we are waiting for Per Moller Andersen. He is one of the 4 owners of Danish company, which still belongs to the families of its founders. The shelves of the meeting room are full of several non alcoholic and alcoholic cold drinks from the range of products that Orskov Foods packs for their customers. One of them contains a mix of oat milk, apple puree and coconut. It would certainly also taste very nice with a bit of blackcurrant puree or concentrate in place of the coconut…

But I have to interrupt my thoughts when Per arrives after finishing his phone call. Immediately, he has to face our questions, because a new sort of packaging caught our eyes. “They are eco cans, from Lamican, a Finnish company. We have started using this new packaging two and a half years ago. I’ll show you how it works when we’ll have a walk through our production unit.” smiles Per. Definitely, tripping Scandinavia is worthwhile!

Products and production units

“We have two production sites here in Denmark. Actually, Orskov Foods A/S is the result of a merge between Ørskov Frugt and Ørbæk Mostfabrik in 2012. Both companies had been founded 80 years ago, and we still have both sites. One packs around 10.000 tons of fresh apples and pears for the Danish retail market yearly, the other one produces between 8 and 10.000 tons of IQF, purees and juices in total.” Orskov Foods doesn’t make any concentrate. They process 60.000 tons of fruit or fruit products with 300 employees. Most amazingly, they still hold 120 hectares of land, where they grow apples and pears.

But of course, around 250 growers in Denmark, Chili and Poland are their partners. With facilities in Poland and Chile for a total of 300 employees, they have a storage capacity of 18.000 m² for fresh, cold and chilled products. Orskov Foods sells fresh fruit in retail (apples, pears and strawberries). But of course, they also produce and sell their own retail juice products in 300, 500 or 1000ml packs.

Three activities at Orskov Foods

Orskov Foods stands on three legs. The production of liquids represents between 5 and 10% of the turnover. “80% of the drinks we produce are apple juices, cold pressed and sterilized”, explains Per Moller Andersen. Fresh apples for the retail market count for 25%. Frozen berries for the industry make up the rest of the turnover. Blackcurrants account for 3000 tonnes in total, out of which less than half stays Danish, the other half comes from Poland. Orskov Foods, Poland was established in 1990 and has now two facilities in the country for soft fruits and vegetables. Another Orskov Foods unit in Chile is still very young: it opened in 2012. It allows to be present with IQF soft fruits in America and opposite season.

Products and production units

Coming back to the eco cans, we wonder where and how Orskov uses them? “Orskov Foods is a specialist in co-packing drinks. Generally, our customers design their packaging and supply the liquids, we do the packing. This is how Lamican approached us for doing the packaging with their eco cans. It is a highly sophisticated way of packing liquids, an alternative and sustainable solution. And thus a tendency in the market”, says Per.

Focus on “Lamicans”

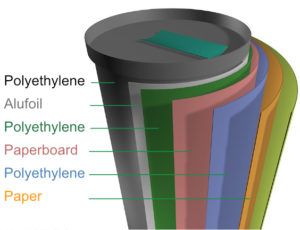

Lamican packages are made up of three materials:

– Paperboard,

– Plastic,

– Aluminum

Lamican is 70% paperboard which is made from wood fibre – a natural and renewable resource when sourced from forests that are responsibly managed, like PEFC.

The cans are fully recyclable with other household cartons, at the recycling plant. Aluminium is the only material at the moment which can prevent oxygen transmission in the long run. Therefore, it is necessary in the production of the cans.

“A LamiCan is clean package that reflects its contents. An aseptic package which has a positive effect on your product. You need less additives, it is risk-free, retains vitamins and other nutritional values for its entire shelf life, and it retains good taste and appearance/colour. Finally, our packages help to reduce everyone’s carbon footprint by avoiding the need for refrigerated transport and storage. In fact, the ‘Lamican’ enables drinks to be stored ambiently and has the lowest carbon footprint when compared to aluminium and PET”, says Tanja Väisänen from the marketing department at Lamican. (More information on alternative packages here.)

“We deliver longer shelf life (6-12 months), distribution without cold chain and retailing without cold chain.”

This system is really impressive. Unfortunately, no blackcurrant product is available in eco cans yet.

After this highly interesting visit, we could return to our Executive meeting refreshed and inspired. Hopefully, you will soon benefit from the decisions we took and from the work we could accomplish after being perfectly refreshed at Orskov Foods.